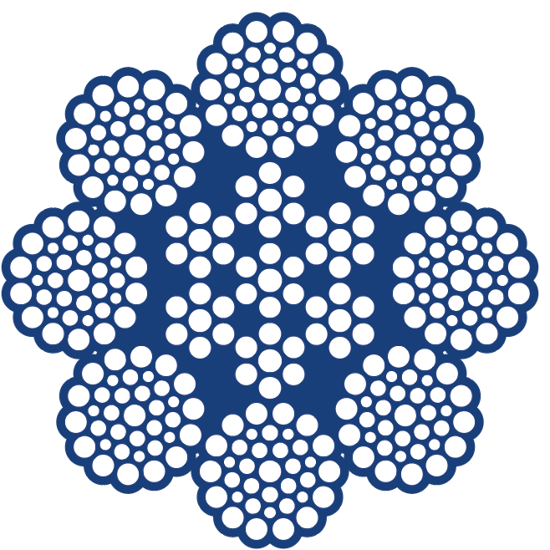

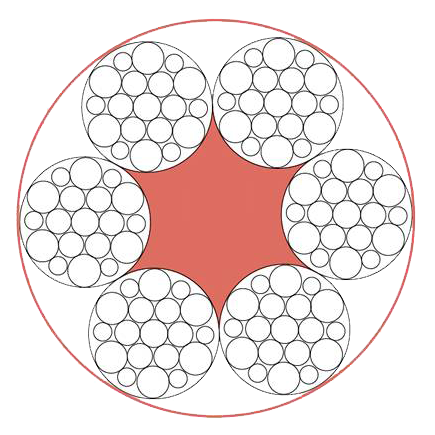

Câble métallique en acier à noyau rembourré avec filtre 8x36WS + IWRC-P, excellent câble métallique de remorquage et de levage

Special Features:

- Compared with the 6 strand wire rope, it has better wear resistance and fatigue resistance.

- The larger external contact area can effectively reduce the wear of the drum and guide wheel.

- Excellent towing and lifting wire rope.

- The unique design combines the latest metallurgical patent technology achievements.

- Better work performance and longer service life.

Technical Table

| Dia | Weight(kg/m) | Minimum Breaking Load(kN) | |

| (inch) | (mm) | ||

| 2 3/8 | 60.3 | 15.029 | 2,440 |

| 2 1/2 | 63.5 | 16.666 | 2,690 |

| 2 5/8 | 66.7 | 18.302 | 2,950 |

| 2 3/4 | 69.9 | 19.790 | 3,210 |

| 2 7/8 | 73.0 | 21.874 | 3,490 |

| 3 | 76.2 | 23.957 | 3,780 |

| 3 1/8 | 79.4 | 26.040 | 4,080 |

| 3 1/4 | 82.6 | 27.974 | 4,380 |

| 3 3/8 | 85.7 | 30.355 | 4,710 |

| 3 1/2 | 88.9 | 32.736 | 5,020 |

| 3 5/8 | 92.1 | 34.968 | 5,360 |

| 3 3/4 | 95.3 | 37.498 | 5,700 |

| 3 7/8 | 98.4 | 39.878 | 6,050 |

| 4 | 101.6 | 42.557 | 6,420 |

| 4 1/8 | 104.8 | 45.235 | 6,780 |

| 4 1/4 | 108.0 | 49.550 | 7,140 |

| 4 3/8 | 111.1 | 52.526 | 7,530 |

| 4 1/2 | 114.3 | 54.163 | 7,920 |

| 4 5/8 | 117.5 | 57.437 | 8,310 |

| 4 3/4 | 120.7 | 60.859 | 8,700 |

| 4 7/8 | 123.8 | 64.133 | 9,120 |

| 5 | 127.0 | 67.555 | 9,530 |

Tips

From the point of view of the user requirements, the wire rope should have the basic performance adapted to the use, which must be paid great attention to in the product design, the manufacturing process and the selection and use of the wire rope. The basic performance and requirements of some common wire rope varieties are described below.

The elevator wire rope is mainly used in the elevator equipment in the high-rise building, so the structure is tight, soft, the structure is extended and the load is small, the lubricating price is good, the safety factor is big, and the fatigue performance is good. In addition, in order to reduce friction with the rope pulley, 8 strands should be used, and the strength of the outer middle steel wire rope should be lower than that of the inner steel wire.

The aircraft wire rope is used mainly as the airliner and the operating cable on the aircraft. Because of the fine specifications and the erosion of the atmospheric medium, it is required to have high fatigue resistance and corrosion resistance.

The mine hoisting wire rope is the force component of the mine carrying material and ore, and it is also the key part of all mines. It requires anti-fatigue, corrosion resistance, wear resistance, small elongation, high life, safe and reliable operation. Besides, it also requires no rotation, loose, and large contact surface with the rope groove.

Overhead cableway steel wire rope and cable car with wire rope overhead ropeway are mainly used as air transportation track, and the cable car is used as a transport tool. The basic requirements for this kind of wire rope are large safety factor, wear-resistant, smooth surface of wire rope, large bending stiffness, the corrosion resistance of atmospheric medium, and not loose. The sealing wire rope and the surface contact wire rope have such performance characteristics.

Lifting wire rope requires high tensile strength, good softness, no rotation, bending fatigue, no loosening, and other basic properties.

In a word, because of the wide use of wire rope, its performance is also diverse. The performance of the wire rope is the quality of the wire rope, and its quality depends on the effective control of the manufacturing process.

Comment commander:

Lors de la commande de câbles en acier, vous êtes prié de nous fournir les informations complètes spécifiées ci-dessous :

un. Objectif : Pour quelle corde sera utilisée.

b. Taille : Diamètre de la corde en millimètres ou en pouces

c. Construction : Nombre de torons, nombre de fils par toron et type de construction des torons.

d. Type de noyau : noyau de fibre (FC), noyau de câble métallique indépendant (IWRC) ou noyau de torons de fil indépendant (IWSC).

e. Pose : pose régulière à droite, pose régulière à gauche, pose lang à droite, pose lang gauche.

F. Revêtement : Brillant (non galvanisé), galvanisé ou inoxydable, PVC ou Graisse.

g. Qualité du fil : Résistance à la traction des fils.

h. Charge de rupture : charge de rupture minimale ou calculée en tonnes ou en livres.

je. Lubrification : si la lubrification est souhaitée ou non, et lubrifiant requis.

j. Longueur : longueur du câble métallique.

k. Emballage : En bobines enveloppées de papier huilé et de toile de jute (orp.p), ou sur des bobines en bois.

l. Quantité : Par nombre de bobines ou de bobines, par longueur ou poids.

m. Remarques : Marques d’expédition et toute autre exigence particulière.

Avis

Il n’y a pas encore d’avis.