What is Hot Dip Galvanized Cable?

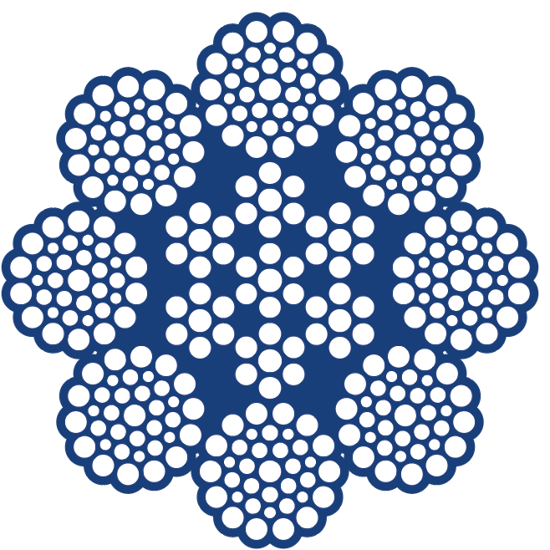

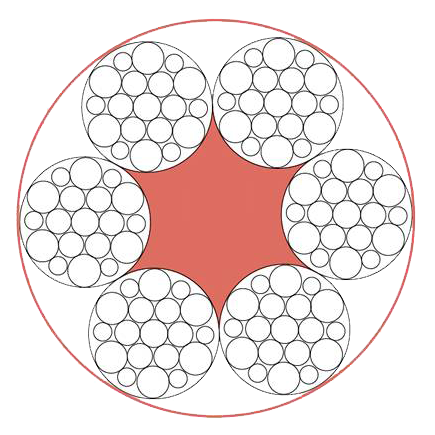

In hot dip galvanized cable, each uncoated steel wire is immersed in a molten zinc bath. Prior to dipping, the wires are put through a rigorous 7-step caustic cleaning process and then dipped into the molten zinc at a temperature of around 860°F/460°C. As it’s withdrawn from the molten bath, the material cools and forms a coating of zinc on the steel. The wires are then formed into strands and then the strands are helically formed into the finished cable or wire rope configuration.

Hot dip galvanizing provides much better corrosion resistance than electro galvanization because the zinc coating is typically 5 to 10 times thicker. For outdoor or caustic applications where corrosion-resistance is required, hot dip galvanized cable is the clear choice.

Advantages of Hot Dip Galvanized Cable

- Longer service life than electro galvanized

- Process creates an iron-zinc alloy layer on the steel surface and a pure zinc coating on the outer surface. The alloy is very hard and resistant to typical abrasions.

- Normal coating thickness can be up to 10 times thicker than electro galvanized coating

Disadvantages of Hot Dip Galvanized Cable

- Dull finish can be streaky, contain drips, and is typically not applicable in architectural or aesthetic applications

- Significantly more expensive than electro galvanized cable (approximately 40% more expensive for comparable products)

- Galvanic thickness can be inconsistent across the product

Lietojumprogrammas

Because it offers superior corrosion resistance compared to electro galvanized cable, hot dip galvanized cable can be used for any application where the cable will be exposed to the natural elements or a caustic environment. Hot dip galvanized cable can be used for fencing or perimeters for construction sites, parking garages, farm and livestock facilities, and much more.

Hot dip galvanized wire rope can also be used for lifting and rigging in crane application and with outdoor winches or pulley systems. Professional zip lines are also another popular use as the cable can withstand corrosion in moist and humid environments.

| Materiāls | cinkots tērauds vai nerūsējošais tērauds |

| Būvniecība | 1 × 7, 1 × 19, 6 × 7, 7 × 7, 6 × 19, 7 × 19 utt |

| Diametrs | 1-20 mm |

| Iepakošana | Koka spoles, spoles |

| HS kods | 7312100000 |

| Izcelsmes vieta | Dzjansu, Ķīna |

| Paraugs | Mēs varam nodrošināt atsauces paraugus, ja tie ir pieejami noliktavā, bet paraugu piegādes izmaksas jāsedz klientam. |

Kā pasūtīt:

Pasūtot tērauda stiepļu trosi, jums ir jāsniedz mums pilnīga informācija, kā norādīts tālāk:

a. Mērķis: kādai virvei tiks izmantota.

b. Izmērs: virves diametrs milimetros vai collās

c. Konstrukcija: dzīslu skaits, vadu skaits vienā dzīslā un dzīslas konstrukcijas veids.

d. Serdes veids: šķiedras serde (FC), neatkarīga stiepļu troses serde (IWRC) vai neatkarīga stiepļu dzīslu serde (IWSC).

e. Gulēšana: labā regulāra gulēšana, kreisā regulāra gulēšana, labā langa gulēšana, kreisā langa gulēšana.

f. Pārklājums: gaišs (necinkots), cinkots vai nerūsējošais, PVC vai smērviela.

g. Stieples pakāpe: Stiepļu stiepes izturība.

h. Pārrāvuma slodze: minimālā vai aprēķinātā pārrāvuma slodze toņos vai mārciņās.

i. Eļļošana: neatkarīgi no tā, vai eļļošana ir vēlama vai nē, un nepieciešamā smērviela.

j. Garums: Stiepļu troses garums.

k. Iepakojums: ruļļos, kas ietīti ar eļļas papīru un Hessian (orp.p) audumu, vai uz koka ruļļiem.

l. Daudzums: pēc ruļļu vai ruļļu skaita, pēc garuma vai svara.

m. Piezīmes: nosūtīšanas zīmes un citas īpašas prasības.

Atsauksmes

Pašlaik atsauksmju nav.