Product Details

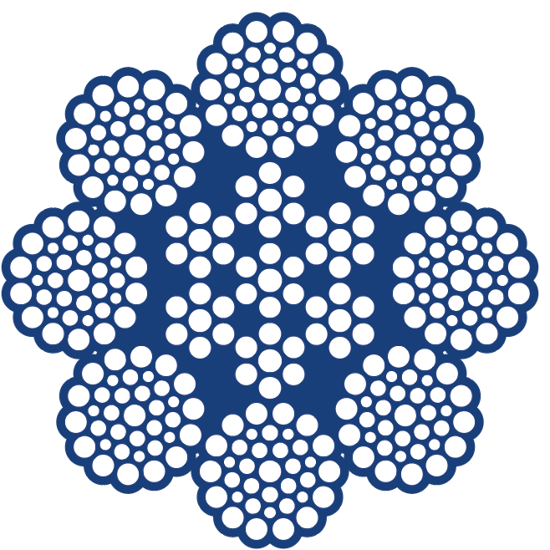

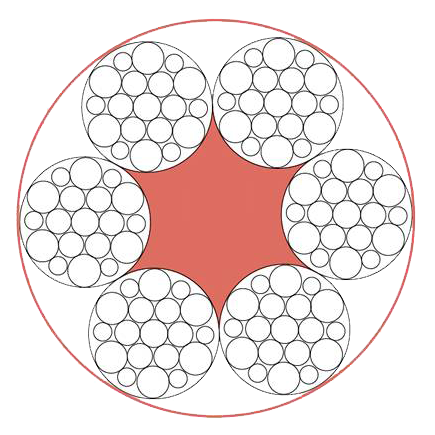

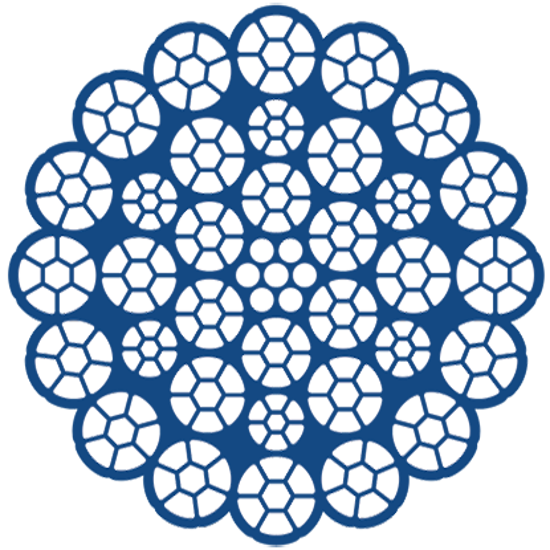

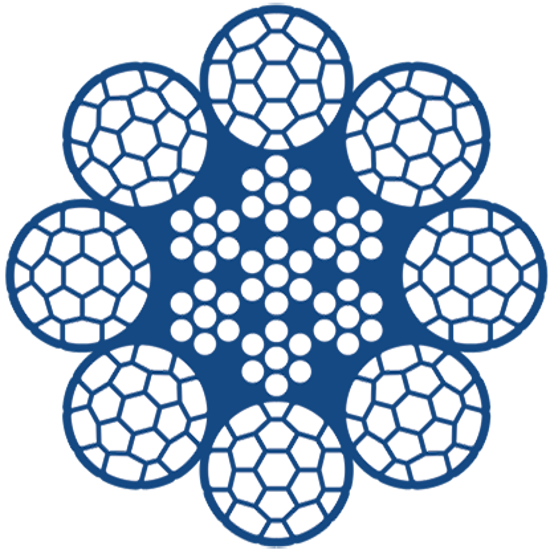

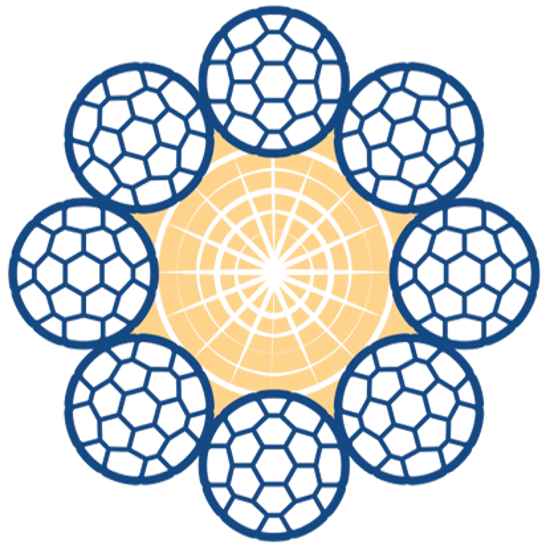

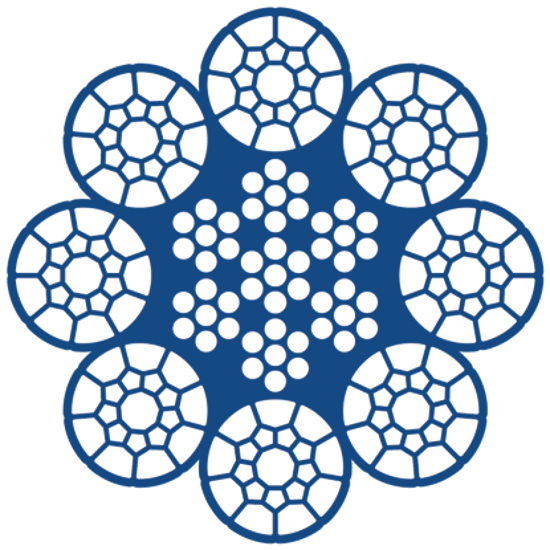

The 35(W)xK7 COMPACT ROTATION RESISTANT WIRE ROPES belongs in the multi strand, rotation resistant classification but its strands are compacted and is used as hoisting wire rope.

Applications

- Offshore crane rope

- Deck crane rope

- Pillar crane rope

- Whip hoist rope

- Main hoist rope

- Crane rope

No comment